Heat Treatment Process For Ferrous Metals

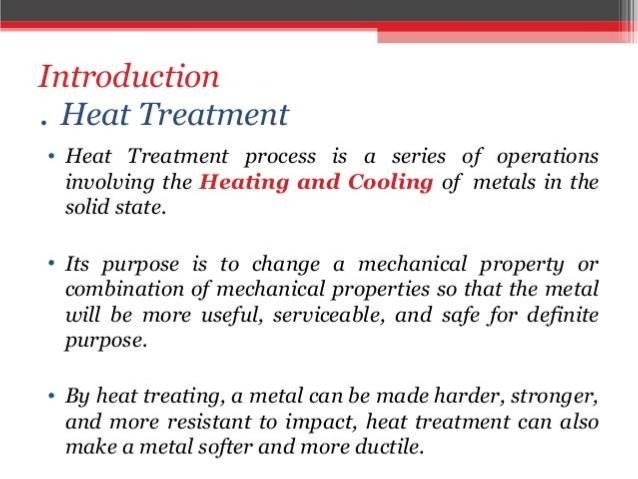

Heat treating is often used to alter the mechanical properties of a metallic alloy manipulating properties such as the hardness strength toughness ductility and elasticity. Austempering is the heat treatment process which is used in case of most of the ferrous alloys especially steel and other alloys.

Heat Treatment Of Ferrous And Nonferrous Metals

Heat Treatment Of Ferrous And Nonferrous Metals

A metal is still considered ferrous even if it contains less than 50 percent iron as long as it contains more iron than any other one metal.

Heat treatment process for ferrous metals. HEAT TREATMENT OF FERROUS METALS STEEL Normalizing Normalizing is a process whereby iron base alloys are heated to approximately 100F 56C above the upper critical temperature followed by cooling to room temperature in still air. This process is applied for ferrous non-ferrous metals as well as glass industry. Above and beyond this thermally active heat treatment method ferrous workpieces are lowered into special salt baths.

Heat treatment Heat treatment involves the use of heating or chilling normally to extreme temperatures To achieve a desired result such as hardening or softening of a material. A ferrous metal has iron as its main element. Normalizing is used to establish materials of the same nature with respect to grain size composition structure and stress.

What are the general steps in heat treating metal. Asides from the application benefits heat treatment is also beneficial to manufacturers. While some heat treatment processesare used for softening some are used for hardening.

While reading up on metallurgy and the process of heat treating in Gastonia NC for use in your industry you may have come across the terms ferrous metals and nonferrous metals. Heating soaking and cooling. By this process we obtain bainite ausferrite and acicular ferrite.

Change the thermal conductivity of a metal. Heating is carried out. It is possible to schedule heat treatments to take advantage of quenching by rapidly reducing the temperature of a steel component to a specific temperature and holding it there.

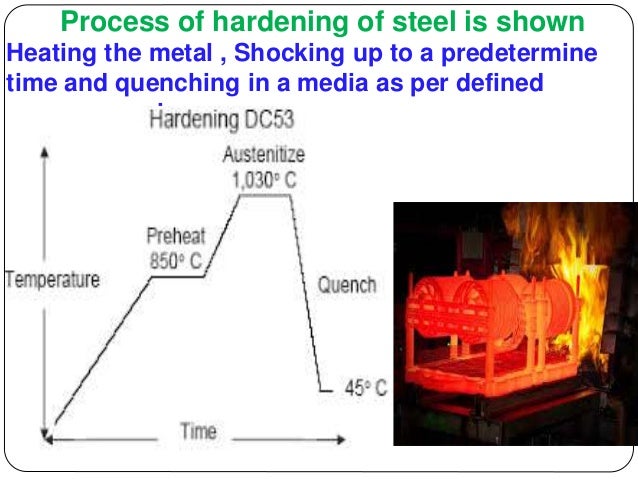

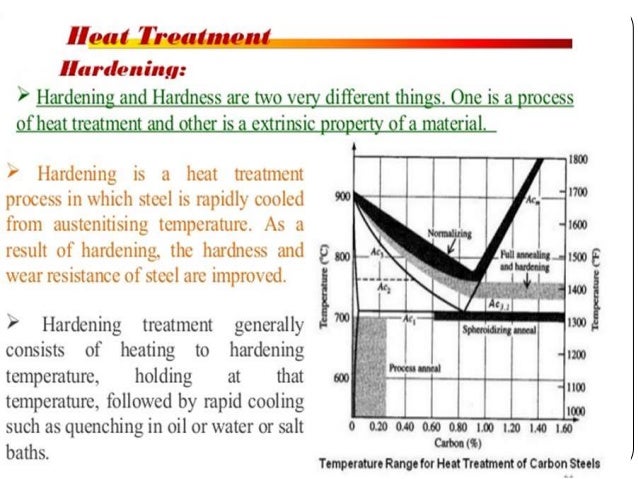

Metal and heat-treating techniques refer to TM 43-0106. The common process of heat treatment of ferrous metals include hardening tempering annealing normalizing and case hardening. Annealing is a heat treatment process wherein the metal is heated above recrystallization temperature held at that temperature for certain duration so as to homogenize the temperature and then cooled at a very slow rate to obtain an equilibrium structure.

For cyaniding a molten bath of cyanide salts hardens the ferrous surface. The microcrystalline grain of a nominated ferrous metal part becomes uniform when its normalized. Heat Treatment Process Steps Heating.

The duration of that. Heat treatment of the metals is one of the best ways to get the desired performance. The Difference Between Ferrous and Nonferrous Metals Used in Heat Treating in Gastonia NC Writer September 15 2016.

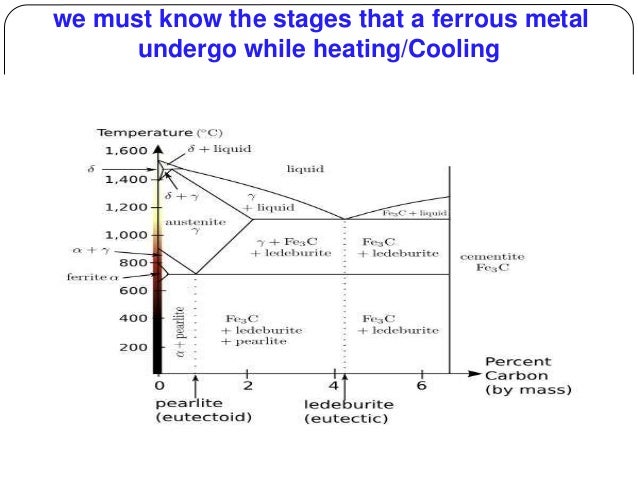

Hardening case hardening annealing normalizing and tempering. As we already discussed the microstructure of alloys will change during heat treatment. The art of controlling the metallurgical properties of steel or any ferrous material is termed heat treatment Through this process the material structure of the metal is altered in order to meet the requirements of a specific application.

Heat treatment provides an efficient way to manipulate the properties of the metal by controlling the rate of diffusion and the rate of cooling within the microstructure. Heating is the first step in a heat-treating process. After the soaking.

A proper heat treatment process help relieves internal stresses. Such a quench and hold treatment allows one particular microstructure as noted on the TTT to form instead of the others. Annealing is a heat treatment process which is used to soften the metal.

In other words annealing helps to improve ductility machinability and toughness. Change a ferrous metal to no-ferrous metal. Annealing does this by changing the microstructure of metals.

The main purpose of using Austempering is to enhance various mechanical properties and to decrease various irregularities inside the metal. None of the above. Increase or decrease the hardness of a metal.

We must know the stages that a ferrous metal undergo while heatingCooling 3. There are five basic heat treating processes. Increase or decrease the hardness of a metal.

In my previous article I have explained The 3 Stages of Heat Treatment Process. A metal is nonferrous if. Heat treatment can be used to.

Heat Treatment process of controlled heating and cooling of metals Alter their physical and mechanical properties without changing the product shape sometimes takes place inadvertently due to manufacturing processes that either heat or cool the metal such as welding or forming. On the flip side the hardness of metals gets reduced. Although each of these processes bring about different results in metal all of them involve three basic steps.

All of the above. During the holding or soaking stage the metal is kept at the achieved temperature. Heat treatment is the process of heating and cooling materials to obtain desired physical properties.

It also helps to develop hard surfaces with ductile base materials. METAL CLASSIFICATION All metals may be classified as ferrous or nonferrous.

Heat Treatment Of Ferrous And Nonferrous Metals

Heat Treatment Of Ferrous And Nonferrous Metals

Heat Treatment Of Ferrous And Nonferrous Metals

Heat Treatment Of Ferrous And Nonferrous Metals

Heat Treatment Of Ferrous And Nonferrous Metals

Heat Treatment Of Ferrous And Nonferrous Metals

What Is The Difference Between Heat Treatment Annealing And Tempering Bright Hub Engineering

What Is The Difference Between Heat Treatment Annealing And Tempering Bright Hub Engineering